Whirring Wonders or Overhyped Gizmos? The Controversial Role of 12V and 24V Car Industrial DC Blower Motors in Engineering Marvels

In the intricate landscape of automotive and industrial engineering, 12V and 24V car industrial DC blower motors emerge as indispensable components, serving a crucial role in ensuring optimal air circulation for a myriad of systems. As the beating hearts of ventilation and air conditioning mechanisms, these motors contribute significantly to the efficiency, comfort, and functionality of vehicles and industrial machinery.

Automotive applications represent a primary domain for the deployment of these DC blower motors. Specifically engineered to operate on 12 volts, these motors find a natural home within the intricate systems that govern the climate control of automobiles. Integrated into heating, ventilation, and air conditioning (HVAC) systems, they play a pivotal role in maintaining a comfortable and controlled environment within the vehicle cabin. The 12V configuration aligns seamlessly with the standard electrical systems of most cars, allowing for efficient integration into the complex network of components that make up modern automotive technology.

Beyond basic temperature control, these blower motors contribute significantly to defroster systems in vehicles. When temperatures drop, and windshields become obscured by fog or ice, the 12V blower motors power defrosters to swiftly clear the view for drivers. This feature is not only critical for safety but also enhances the overall driving experience, ensuring clear visibility in challenging weather conditions.

In the industrial realm, where the demands on air circulation and climate control are diverse and dynamic, the 24V car industrial DC blower motors find their niche. In large industrial spaces, HVAC systems equipped with these motors ensure that air quality is maintained at optimal levels, contributing to the well-being of workers and the efficiency of industrial processes. The 24V configuration, commonly used in industrial settings, aligns with the electrical standards of many industrial applications, making these motors a suitable choice for a wide range of environments.

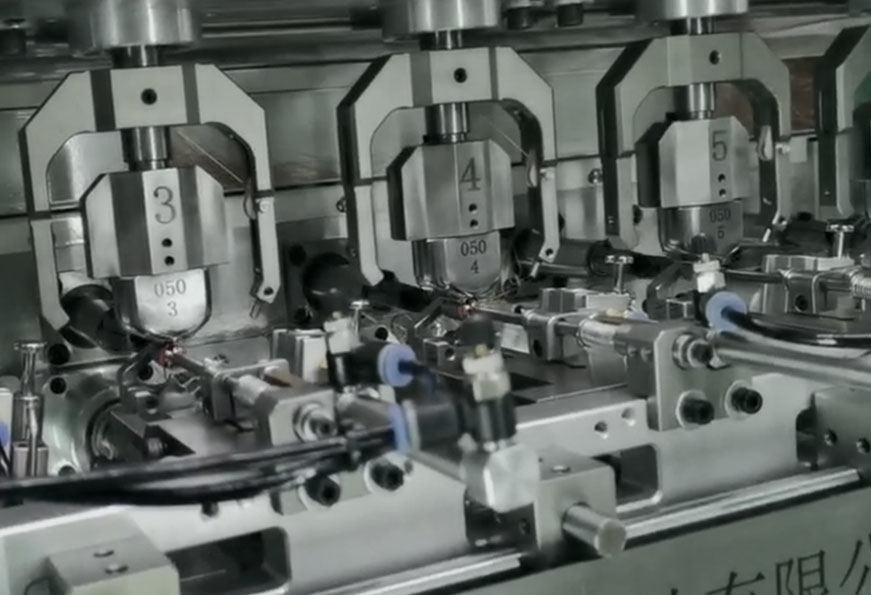

These versatile blower motors extend their influence beyond conventional HVAC systems. In industrial machinery, particularly those with electronic components, the demand for efficient cooling is paramount. The 24V car industrial DC blower motors play a pivotal role in dissipating heat generated by these electronic systems, ensuring that machinery operates within optimal temperature ranges. This cooling capability not only enhances the performance of industrial equipment but also prolongs the lifespan of critical electronic components, contributing to the overall reliability of the machinery.

One notable feature of these DC blower motors is their compact design, a critical attribute for their integration into the confined spaces of vehicles and industrial equipment. The compact form factor allows for flexible placement within the limited spaces available in car interiors or industrial machinery, ensuring efficient use of available real estate.

Moreover, the durability of these blower motors is a testament to their resilience in the face of challenging operating conditions. Engineered to withstand the vibrations, temperature variations, and environmental factors inherent in both automotive and industrial settings, these motors deliver reliable performance over the long term. This durability is particularly crucial in applications where downtime due to motor failure could have significant operational and financial implications.

Noise considerations are paramount in the automotive realm, where a quiet and comfortable interior is a key aspect of the driving experience. Many 12V and 24V car industrial DC blower motors are designed to operate with minimal noise, ensuring that the circulation of air within the vehicle cabin remains imperceptible to the occupants. This emphasis on a quiet operation adds to the overall refinement of the driving experience, enhancing the comfort and satisfaction of vehicle users.

Qualitas procuratio

Qualitas procuratio Experientia export

Experientia export