Peniculus Motors Revelata: Suntne DC Electronic Fans cum perterget aevum Titanas vel Just Setulose Has-Beens?

Definitio notarum DC electronicarum ventilationum in intricato ac probato consilio motoris sui consistit, qui perterget et commutatorem incorporat. Tradita haec conformatio motoria, dum, ut videtur, directa, clavem habet functionis ventilationis et fortis in rerum electronicarum refrigeratione per decennia fuit.

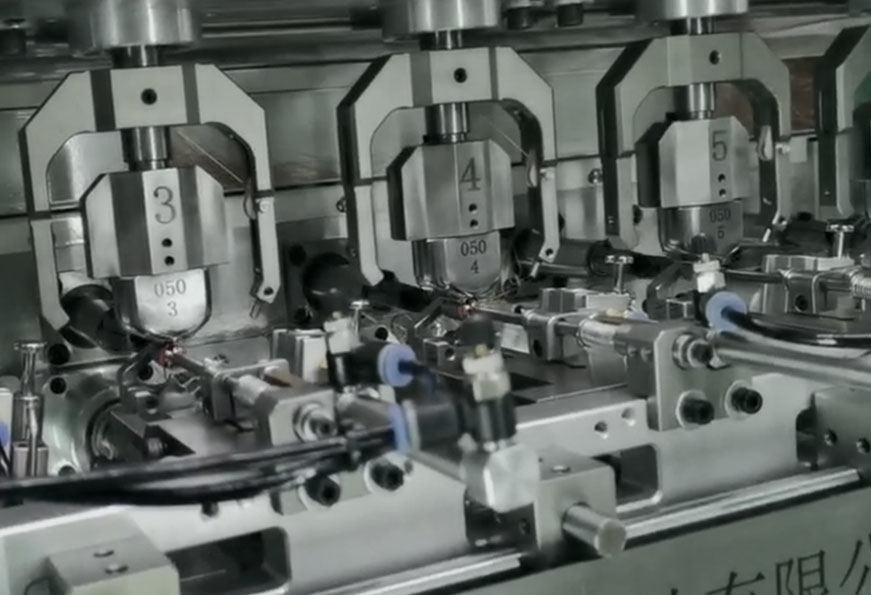

In corde tabulae electronicae DC scopuli est motor scopulorum, systema electromechanicum classicum. Motor duo elementa essentialia complectitur: perterget et commutatorem. Seti, ex carbo vel aliis materiis conductivis typice factis, continuam electricam contactum cum commutatore nere conservant, quae structura cylindrica divisa plerumque ex cupro facta est.

Commutator elementum cruciale inservit in creatione campi magnetici ad operationem mobilem necessariam. Sicut electricus vena per virgulta et in commutatorem fluit, natura divisa commutatoris iungitur. Commercium inter setas et segmenta commutatoria efficit ut directio hodiernae in gyro motoris incommodis momento temporis exigatur ad conversionem motoriam custodiendam. Haec conversio directionis hodiernae essentialis est ad conservandum motum gyrativum motoris.

Seti, in constanti contactu cum commutatore, agunt pontes conductivi, ut profluat vena electrica et creatio campi magnetici in gyro motore. Hic campus magneticus cum magnetibus permanentibus vel aliis componentibus magneticis intra motorem se mutuo agit, causando scapum motoricum ad rotandum. Cum hastile motoris se vertit, laminas ventilationum agit, principians airflow necessariam ad calorem dissipationis in electronicis machinationibus.

Dum consilium motoricum firmum et late adhibitum est, non sine considerationibus est. Insignis aspectus est vestis et lacrima cum setis sociata. Subinde perterget paulatim ob attritionem et contactum cum commutatore rotante terunt. Hic vestis naturalis consecutio naturae mechanicae systematis est et factor praecipuus in considerationibus electronicis electronicis DC praestrictus est.

Indumentum in perterget deduci possunt ad efficientiam et mutationes reducendas in contactu electrici inter pertergetem et commutatorem. Ut perterget gerunt, requirant reponendam ad meliorem motricem perficiendam conservandam. Haec periodica sustentatio propria est aspectus motorum obstrictorum et consideratio ratio designantium et usorum innixa his ventilationibus ad refrigerationem electronicam.

Praeter lapsum in perterget, alia consideratio cum consilio motoris scopulorum consociata est generatio sonitus electrici. Continuus contactus et separatio setis ex segmentis commutatoribus strepitum electricam producere possunt, ad altiorem acusticam signaturam ventilationis in operatione conferentes. Hic campus strepitus potest esse factor in applicationibus ubi operatio quietior desideratur.

Quamvis hae considerationes, consilium motoris praestrictum remanet ad propositum et late adhibitum in variis applicationibus electronicarum refrigerationis. Eius simplicitas et sumptus-efficacia electionem attractivam faciunt, praesertim in missionibus ubi beneficia praeponderant ad sustentationem requisita. Versatilitas et aptabilitas electronicarum dc scoparum electronicarum tractantium, cum diversis amplitudinibus et notis custo- salibus, curent ut partes vivas agere pergant in machinis electronicis per spectrum applicationum.

Qualitas procuratio

Qualitas procuratio Experientia export

Experientia export